Online monitoring system for locomotive high-voltage lightning arrester

System Overview

High voltage lightning arresters are responsible for protecting locomotive high-voltage electrical equipment from overvoltage damage, and their own operating status directly affects whether the locomotive can operate safely and stably. At present, accidents of lightning arresters breaking during locomotive operation still occur, and the main reasons involve the following:

The performance of lightning arresters deteriorates under the influence of external factors, resulting in significant changes in their operational status

The transient overvoltage multiple of the contact network power supply is too high, exceeding the range that the lightning arrester can withstand

Under dynamic conditions of vehicle and network operating parameters, there is an imbalance in matching, resulting in systematic resonance

To ensure the safety of locomotive operation, it is important to ensure that the operation and maintenance personnel are fully aware of the operating status of high-voltage lightning arresters and the power supply status of the system during locomotive operation, and to take reasonable measures according to the actual situation to avoid accidents; Real time detection of potential hazards and faults in lightning arresters based on their characteristic parameters and trends in state changes is an important measure to reduce the occurrence of accidents by achieving early detection and handling.

The online monitoring system for the operation status of locomotive high-voltage lightning arresters realizes real-time online monitoring, warning analysis, state evaluation, and primary fault diagnosis of the operating characteristic parameters of locomotive high-voltage lightning arresters (including leakage current, resistive current, capacitive current, resistance capacitance ratio, action frequency, action time) and contact network operation data (including voltage, frequency, 1-20 harmonics, total harmonic distortion); The system simultaneously records and analyzes waveform data of relevant quantities (network voltage, impulse current, and lightning arrester leakage current) at the time of lightning arrester action, providing technical support for manual fault analysis.

The application of an online monitoring system for the operation status of locomotive high-voltage lightning arresters can achieve self detection and self diagnosis of lightning arrester operation status, greatly improving the safe operation level of lightning arresters. Through long-term operation, the system can accumulate operational data of lightning arresters under different working conditions, establish a standard model for evaluating the health status of lightning arresters and a fault diagnosis model for lightning arresters, achieve full life cycle management of lightning arresters, accurate evaluation of operational status, intelligent identification of fault types, and guide lightning arrester maintenance work.

Two system components

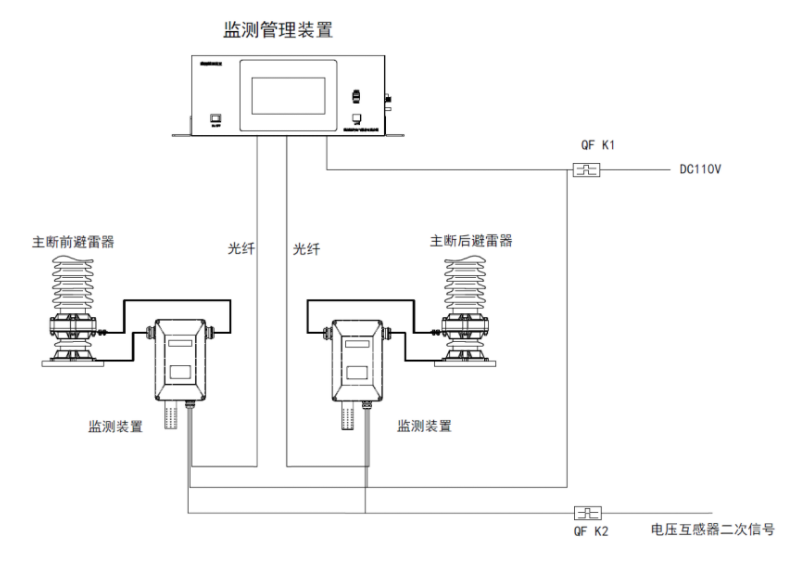

The system equipment is deployed in two layers, namely the front-end lightning arrester monitoring device and the back-end lightning arrester monitoring management device.

The lightning arrester monitoring device is deployed near the lower part of the lightning arrester body to complete signal acquisition, processing, and calculation. At the same time, real-time monitoring data and transient waveform data recorded during the action of the lightning arrester are uploaded to the back-end monitoring management device through a communication interface.

The lightning arrester monitoring and management device is deployed in the electrical cabinet of the carriage, completing the collection, caching, analysis, evaluation, and primary diagnosis of monitoring data. The alarm information, status evaluation information, and real-time monitoring data output by the monitoring and management device are displayed on the built-in display screen, providing technical support for vehicle operation and maintenance personnel.

All cached data and analysis result data of the monitoring and management device can be backed up through the USB interface of the device, achieving big data accumulation and trend analysis of operating status.

Three system functions

3.1 Real time monitoring of operational data

The lightning arrester monitoring system collects the following parameters every minute:

3.2 Transient process recording and analysis of actions

The system automatically records the waveform data of the network voltage (sampling rate of 200KSPS), impulse current (sampling rate of 4MSPS), and full current (sampling rate of 200KSPS) before and after the action of the lightning arrester (20ms before and 20ms after the action). When conducting cause analysis after an accident, the system provides recorded waveforms and network voltage analysis data (including voltage frequency, peak value, 1-20th harmonic voltage values, and total harmonic distortion THD value) to support manual analysis.

3.3 Risk Warning

Based on the operating parameters of lightning arresters, threshold comparison method and trend analysis method are used to evaluate the current operating risks of lightning arresters and output warning information, so as to detect and solve safety hazards of lightning arresters early and prevent operational accidents from occurring.

3.4 Evaluation of Operational Status

Comprehensively analyze the operating characteristic parameter values of lightning arresters (full current, resistive current, resistance to capacitance ratio), environmental parameters (temperature, humidity), refer to relevant specifications of the State Grid, and combine our company's experience in the maintenance process of lightning arresters to conduct real-time evaluation of the operating status of lightning arresters. The evaluation of the operation status of lightning arresters is divided into four levels: normal, attentive, abnormal, and severe.

3.5 Primary Fault Diagnosis

When warning information appears, combined with status evaluation information, the primary fault diagnosis module provides biased diagnostic opinions and suggested focus points. Due to the lack of online monitoring data accumulation and sample data of faulty lightning arresters, as well as the absence of mature diagnostic models in the industry, this system establishes a primary diagnostic model by mining lightning arrester maintenance data and combining it with industry standards. Under the condition of limited fault samples during the initial operation of the system, the primary diagnostic model has certain guiding significance for the maintenance of lightning arresters; After the later model is perfected, the diagnostic results can guide the maintenance of lightning arresters and achieve the goal of intelligent operation and maintenance.

Implementation of Four System Functions

The online monitoring system for lightning arrester operation status is equipped with a 7-inch touch screen for onboard monitoring and management. It outputs monitoring data, status evaluation results, and diagnostic results to onboard engineers, and distinguishes warning severity levels, status evaluation results, and diagnostic prompt information in different colors.

In addition, the system provides a web login browsing mode. When the monitoring system sends out abnormal prompt information, professional engineers can access real-time monitoring data, query and analyze monitoring data through web login. At the same time, they can also optimize warning settings, status evaluation and fault diagnosis models through configuration.

Five system technical indicators

Full current measurement range: 0.1-50mA

Full current measurement error: ± (Rd * 1%+5uA)

Measurement range of resistive current: 0.01-10mA

Measurement error of resistive current: ± (Rd * 2%+5uA)

Capacitive current measurement range: 0-50mA

Measurement error of capacitive current: ± (Rd * 2%+10uA)

Resistance capacitance ratio measurement range: 0.01~0.5

Measurement error of resistance capacitance ratio: ± (Rd * 2%+0.005)

Range of lightning arrester action count: 0-4000000

Error in the number of lightning arrester actions: ± (Rd × 3%)

Frequency measurement range: 45-65Hz

Frequency measurement error: ± 0.002Hz

Voltage measurement range: 0-270V (measurement range can be expanded according to actual situation)

Voltage measurement error: ± (standard reading x 0.5%)

Harmonic voltage measurement: 1-20th harmonic

Harmonic voltage measurement error: ± (standard reading x 3%)

Temperature measurement range: -40 ℃ to+100 ℃

Temperature measurement error: ± 1 ℃

Humidity measurement range: 5-95% RH

Humidity measurement error: ± 5% RH

Performance indicators of six monitoring devices

● Insulation performance

Under normal test atmospheric conditions, measure the insulation resistance with a 500V megohmmeter, and the test results meet the following requirements:

a) The insulation resistance of the power supply to ground shall not be less than 100M Ω.

b) The insulation resistance of the PT secondary voltage input circuit to ground shall not be less than 100M Ω.

c) The insulation resistance between live circuits without electrical connection shall not be less than 100M Ω.

● Medium strength

The withstand frequency is 50Hz ± 5Hz and the AC sine wave test values listed in the table below are tested for 1 minute without insulation breakdown or flashover.

Subject circuit |

Rated insulation voltage level Ui (V) |

Test voltage (V) |

Whole machine lead out terminal - ground |

60~250 |

two thousand |

Communication circuit - ground |

60~250 |

two thousand |

The live part of the whole machine - ground |

≤60 |

five hundred |

● Electromagnetic compatibility capability

GB/T 17626.2-2006 Electrostatic Discharge Immunity Test Level 4, Performance A

GB/T 17626.3-2006 Radio Frequency Electromagnetic Field Radiation Immunity Test Level 3, Performance A

GB/T 17626.4-2008 Electrical Fast Transient Pulse Group Immunity Test Level 4, Performance A

GB/T 17626.5-2008 Surge (Impact) Immunity Test Level 4, Performance A

GB/T 17626.6-2008 Conducted Disturbance Immunity Test for Radio Frequency Field Induction Test Level 3, Performance A

GB/T 17626.8-2006 Power Frequency Magnetic Field Immunity Test Level 5, Performance A

GB/T 17626.9-1998 Pulse Magnetic Field Immunity Test Level 5, Performance A

GB/T 17626.10-1998 Damping oscillation magnetic field immunity test level 5, performance A

GB/T 17626.11-2008 Voltage sag, short interruption and voltage variation immunity test

Voltage sag test: 40% UT, 0.2s 70% UT, 0.5s 80% UT, 5s short interruption: 0% UT, 0.5s Performance A

Product

Download

Solution

Contact

Wechat

WechatCopyright © 2026 powered by Wuhan Yikun Xianjian Electric Co., Ltd. 鄂ICP备2021022314号-1